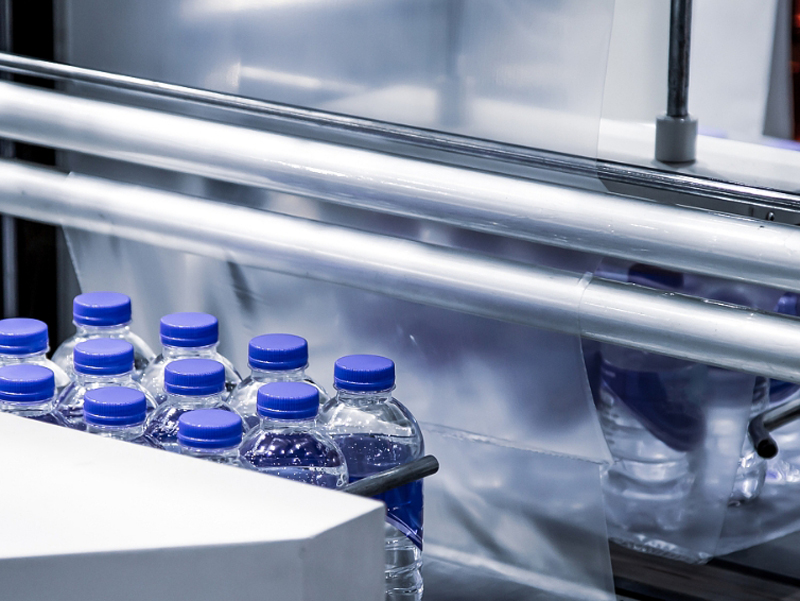

In the packaging machinery industry, there are many applications of load cells, most of which are quantitative inspection and weighing scales and conveying and sorting scales. A key use of these sensors is in-line detection of weight inconsistencies, missing parts or instructions during packaging. They provide feedback to packaging equipment to ensure products meet specifications and requirements, optimize material usage, and improve overall product quality. The product itself is composed of a weighing conveyor, a controller and an in-out material conveyor. The weighing conveyor is responsible for collecting the weight signal and sending it to the controller for processing, while the infeed conveyor is responsible for increasing the product speed and creating enough space between items. In turn, the discharge conveyor plays a vital role in transporting test products from the weighing area and eliminating any defective items. If you are looking for the best type of sensor, consider single point load cells, bellows load cells or S-type load cells.