The year 2020 brought many events that no one could have foreseen. The new crown epidemic has affected every industry and changed the lives of millions of people around the world. This unique phenomenon has led to a significant surge in demand for masks, PPE, and other nonwoven products. Exponential growth has made it difficult for manufacturers to keep up with the rapidly growing demand as they seek to increase machine productivity and develop expanded or new capabilities from existing equipment.

As more manufacturers rush to retrofit their equipment, the lack of quality nonwoven tension control systems is leading to higher scrap rates, steeper and more costly learning curves, and lost productivity and profits. Since most medical, surgical, and N95 masks, as well as other critical medical supplies and PPE, are made from nonwoven materials, the need for higher quality and higher quantity products has become a focal point for quality tension control system requirements.

Non-woven is a fabric made from a blend of natural and synthetic materials, fused together by various technologies. Melted non-woven fabrics, mainly used in mask production and PPPE, are made from resin particles which are melted into fibers and then blown onto a rotating surface: thus creating a single-step fabric. Once the fabric has been created, it needs to be fused together. This process can be carried out in one of four ways: by resin, heat, pressing with thousands of needles or interlocking with high speed water jets.

Two to three layers of non-woven fabric are needed to produce the mask. The inner layer is for comfort, the middle layer is used for filtration, and the third layer is used for protection. In addition to this, each mask requires a nose bridge and earrings. The three non-woven materials are fed into an automated machine that folds the fabric, stacks the layers on top of each other, cuts the fabric to the desired length, and adds the earrings and nose bridge. For maximum protection, each mask must have all three layers, and the cuts need to be precise. To achieve this precision, Web needs to maintain proper tension throughout the production line.

When a manufacturing plant produces millions of masks and PPE in a single day, tension control is extremely important. Quality and consistency are the results every manufacturing plant demands every time. A Montalvo tension control system can maximize a manufacturer’s end product quality, increase productivity and product consistency while solving any tension control related problems they may encounter.

Why is tension control important? Tension control is the process of maintaining a predetermined or set amount of pressure or strain on a given material between two points while maintaining uniformity and consistency without any loss in material quality or desired properties. In addition, when two or more networks are brought together, each network may have different characteristics and tension requirements. To ensure a high-quality lamination process with minimal to no defects, each web should have its own tension control system to maintain maximum throughput for a high-quality end product.

For precise tension control, a closed or open loop system is critical. Closed-loop systems measure, monitor and control the process through feedback to compare actual tension with expected tension. In doing so, this greatly reduces errors and results in the desired output or response. There are three main elements in a closed loop system for tension control: the tension measuring device, the controller and the torque device (brake, clutch or drive)

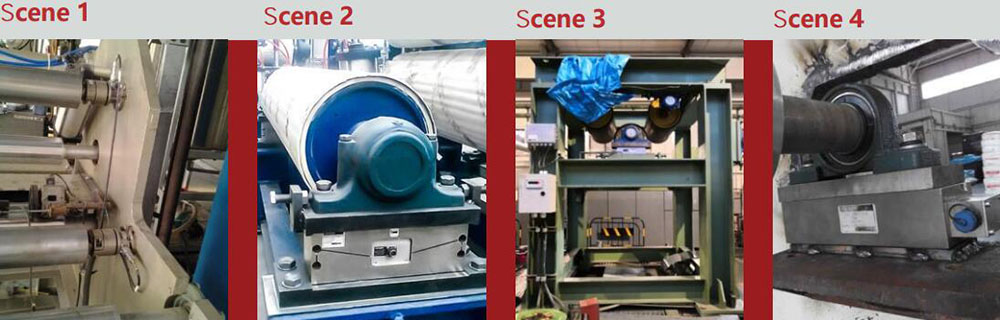

We can provide a wide range of tension controllers from PLC controllers to individual dedicated control units. The controller receives direct material measurement feedback from the load cell or dancer’s arm. When the tension changes, it generates an electrical signal which the controller interprets in relation to the set tension. The controller then adjusts the torque of the torque output device (tension brake, clutch or actuator) to maintain the desired set point. In addition, as the rolling mass changes, the required torque needs to be adjusted and managed by the controller. This ensures that the tension is consistent, coherent and accurate throughout the process. We manufacture a variety of industry-leading load cell systems with multiple mounting configurations and multiple load ratings that are sensitive enough to detect even small changes in tension, minimizing waste and maximizing the amount of high-quality final product. The load cell measures the micro-deflection force exerted by the material as it moves on the idler rolls caused by tension tightening or loosening as the material passes through the process. This measurement is made in the form of an electrical signal (usually millivolts) that is sent to the controller for torque adjustment to maintain the set tension.

Post time: Dec-22-2023