1. Program overview

Shaft metering mode (dF=2)

1. The indicator automatically locks and accumulates the axle weight that has passed the platform. After the vehicle passes the weighing platform as a whole, the locked vehicle is the total weight. At this time, other operations can be performed in static mode. After all operations are completed, press the [ZERO] button Or press the [Weighing] key to release the lock, or press the [Input] key to “finish” (Note 5-2-1), and wait for the weighing of the next vehicle.

2. If the axle of the vehicle stays on the weighing platform for a long time, the indicator will display the static weight of the current axle. At this time, you can press [F1] key to save manually to realize the function of static axle measurement.

3. In order to avoid the loss of the axle or the short interval time (<0.1S = resulting in inaccurate weighing), the user is strongly recommended to select the appropriate length according to the actual needs of the site Weighing platform to fit the shaft or to ensure that two adjacent shafts can be distinguished.Note: The weighing platform is too short may affect the accuracy and repeatability of weighing.

Note 5-2-1: Pressing the [Input] key only “ends” but does not release the lock; however, the indicator can automatically release the lock when measuring the next vehicle and restart the axis measurement from the first axis.

Considerations for Dynamic Operation

1. In the dynamic mode, the weighing is carried out during the process from the vehicle (or a certain axis) on the scale platform to the next scale platform, so it is necessary to avoid the variable speed movement of the vehicle on the scale platform or the introduction of other disturbances, otherwise the weighing accuracy will be affected.

2. The vehicle must pass through the weighing platform at a constant speed within the specified speed. Excessive speed may reduce the accuracy and repeatability of weighing. We are willing to use advanced technology, long-term accumulated experience, reliable quality, reasonable price, and high-quality service to provide contribute to the development of your company.

2.Supply list

| No. | Name | Model Specifications | Parameter Description | Quantity | Remark |

| 1 | weighing platform | SCS-D-2t | stainless steel,C3 | 1 | Contains 4 load cells, 1 junction box |

| 2 | transmitter | XK3190-DM1 | 4-20mA | 1 |

3. Implementation standards

Electrical Control Equipment” GB/T 3797-2016

Enclosure Protection Level” GB4208-2008

4. Working environment

Temperature: -30~70℃;

Humidity: 20~90%, no condensation;

5. System introduction

Weighing and control system composition plan: automobile axle load scale weighing platform, display instrument.

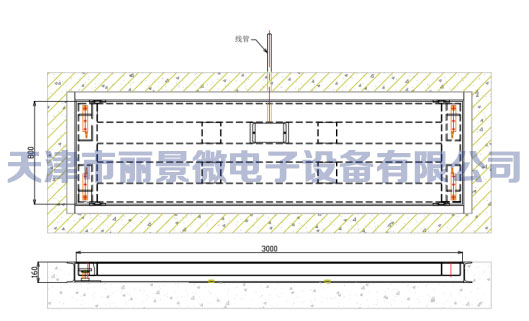

5.1. Vehicle axle load scale weighing platform

5.2. display instrument

XK3190-M1 is a dynamic and static dual-purpose truck scale weighing display with excellent performance. Users can set the instrument to three working modes: dynamic vehicle, dynamic axle measurement and static according to their own needs.

In this scheme, the working mode of dynamic axis measurement is mainly adopted. (see manual for details)

6. Quality and Implementation

In order to ensure that the technical indicators can meet the needs of users, our company designates a product manager as the technical person in charge throughout the project execution process to conduct technical communication throughout the process to ensure the consistency and unity of technical information between customers and the company.

6.1 Packaging and transportation

In order to facilitate project management, the packaging adopts the unified packaging of the “Equipment, Material Packaging, Storage and Transportation Regulations” formulated by the company. The packaging is packed in wooden boxes to ensure that the equipment is not damaged during transportation and loading and unloading. Our company promises: If it is damaged during transportation due to packaging problems, it will be responsible for replacement.

The transportation method adopts automobile transportation, and the packaging method adopts the necessary packaging suitable for transportation. At the same time, our company does a good job of protecting the equipment to ensure that the equipment will not be damaged during transportation, loading and unloading, and storage.

6.2 Installation and commissioning

Our company actively cooperates with the buyer’s work. According to the progress of the project, our company will guide the installation and commissioning by free phone or video; if necessary, we can send personnel to the site for guidance, and the site fee will be negotiated separately.

6.3 Guarantee system

Technology assurance, sophisticated R&D equipment and rigorous testing methods ensure the high reliability of products. After years of technology accumulation and precipitation, the company has obtained more than 30 authorized patents. Products undergo EMC testing, environmental testing, functional testing, etc., to meet the requirements of performance indicators.

Quality assurance system,Labirinth adheres to the quality policy of “quality-oriented, excellence, and customer satisfaction”, and all key components are imported with original packaging according to customer needs, with quality assurance.

Post time: Jul-29-2023